Attentions Of SMT Equipment Operation

Attentions Of SMT Equipment Operation

Jun.18.2021

The operation of SMT equipment requires good technical operation. Different equipment has different precautions. What are the precautions?

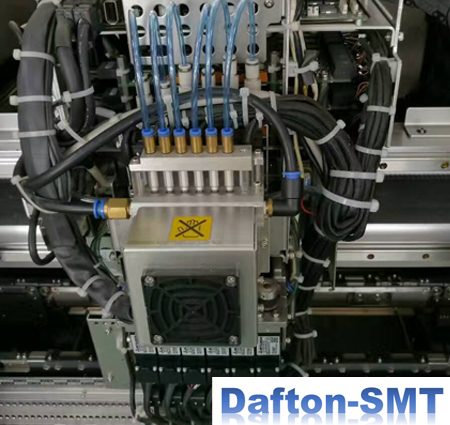

The Principle Of SMT Machine

The Principle Of SMT Machine

May.21.2021

The SMT feeder and PCB substrate are fixed, the placement head which installed with some vacuum nozzles moves back and forth between them, takes out the component from the feeder,adjusts the position and direction...

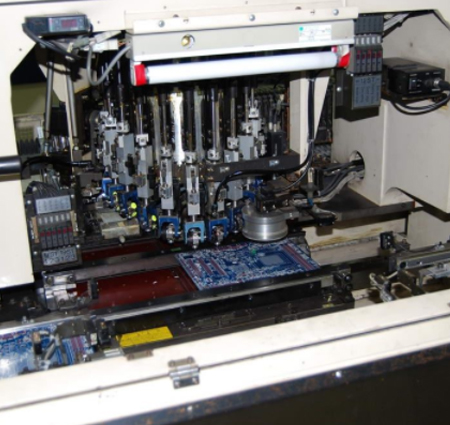

SMT in use

SMT in use

Apr.15.2021

Mass produced electronic circuit boards need to be manufactured in a highly mechanised manner to ensure the lowest cost of manufacture. The traditional leaded electronic components...