Types Of SMT Feeder

Types Of SMT Feeder

Jun.18.2021

What is the SMT feeder? SMT Feeder is the most important part of SMT machine and also an important part of SMT that affects the mounting capacity and production efficiency. Some SMT machines directly use the number of loadable feeders as a sign.

Attentions Of SMT Equipment Operation

Attentions Of SMT Equipment Operation

Jun.18.2021

The operation of SMT equipment requires good technical operation. Different equipment has different precautions. What are the precautions?

SMT in use

SMT in use

Apr.15.2021

Mass produced electronic circuit boards need to be manufactured in a highly mechanised manner to ensure the lowest cost of manufacture. The traditional leaded electronic components...

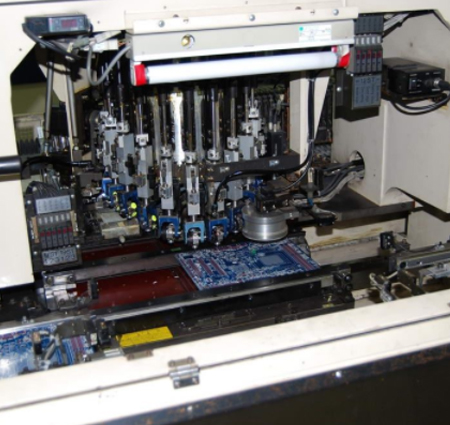

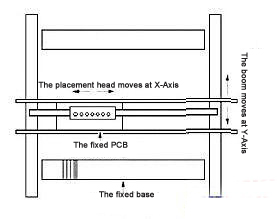

them, takes out the component from the feeder,adjusts the position and direction of the component and finally mounts it on the substrate.The placement head is installed in the X/Y moving beam of gantry, hence the name.

them, takes out the component from the feeder,adjusts the position and direction of the component and finally mounts it on the substrate.The placement head is installed in the X/Y moving beam of gantry, hence the name. The smt feeder is put on a cart moving at a single axis, PCB substrate is put on work table moving at X/Y-Axis system and the placement head is installed on a turret.When they are working, the cart moves the feeder to feeding position where the smt nozzle takes the component, rotating to the mounting position that 180°with feeding position by the turret.Finally mounting the component on the substrate through adjusting the position and direction of the component when rotating.

The smt feeder is put on a cart moving at a single axis, PCB substrate is put on work table moving at X/Y-Axis system and the placement head is installed on a turret.When they are working, the cart moves the feeder to feeding position where the smt nozzle takes the component, rotating to the mounting position that 180°with feeding position by the turret.Finally mounting the component on the substrate through adjusting the position and direction of the component when rotating.